Cap Compression Molding Machine

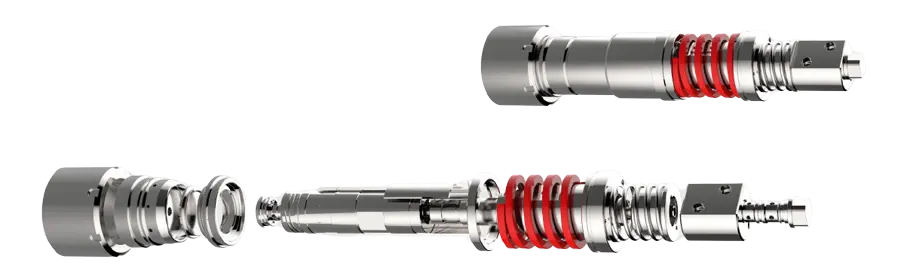

JOBO CMM CAP MOULD

How It Works?

The Plastic Pellets are heated and melted plastic is injected into a mold cavity. The Mold cavity is then compressed by a rotary compression system, which forms the plastic into the desired shape of the cap. The cap is then cooled and ejected from the machine. This process is efficient and produces high-quality caps with consistent dimensions.