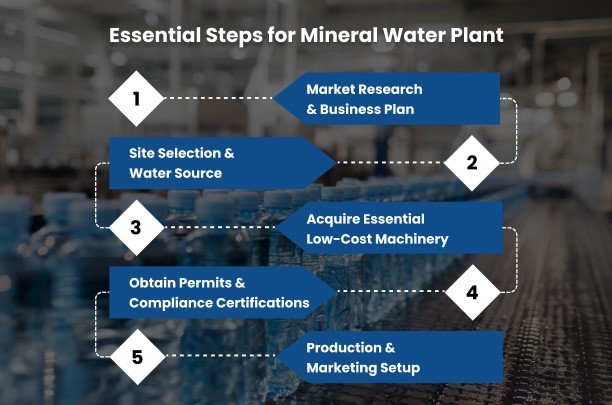

In today’s health-conscious society, the demand for mineral water has increased rapidly offering a better opportunity for entrepreneurs. Setting up a mineral water plant can be tough task, but the hardest thing is finding the right machines at a good price. Starting a Mineral Water Plant involves understanding the market, rules and regulations and the detailed production process to ensure that your business is well-founded.

The first important step involves selecting the right machinery, from R.O plant to packaging machinery. Making sure you have a reliable water source also you are getting the right Machinery for Water treatment, packaging and safety is very important. Knowing these details will help you plan and start your bottle mineral water plant, making sure you are ready for all the important steps in bottling Industry.

Identify Target Consumers and Market Area: Understand who your potential customers are and where they are located. Analyze consumer preferences, pricing strategies, and demand trends to tailor your offerings effectively.

Analyze Competitors: Evaluate the strengths and weaknesses of existing competitors in the mineral water Plant market. This will help you position your product strategically to gain a competitive edge.

New Geographic Regions: You should look into expanding your business into new areas, including international markets. So, it is advisable to focus on regions that show high growth potential for bottled water consumption.

Customer Segments : You can identify and target new customer segments that have specific needs and preferences for bottled water.

Health and Safety: The growth of the bottled water market is largely because of consumer concerns over health issues related to contaminated water and the lack of drinking water in various regions.

An Ideal Location: You need a place where you can easily get lots of water, that's reliable and won't run out. It keeps your mineral water plant working well without any interruptions.

Water Source: You need to make sure the water nearby is good enough for making mineral water. Test it often to make sure it's clean and safe. This way, you can be sure that the water you're using is always clean and safe for everyone to drink.

Water Treatment Systems: Include sand filter, Activated Carbon Filter, Absolute Micron Cartridge Filter, High Pressure pump, Reverse Osmosis System, Antiscalant Dosing, Ultraviolet Sterilizer, Product water storage tank, Ozone generator, and dosing systems.

Bottling and Packaging: Equip your mineral water plant with bottle blowing machinery, filling machines for bottles , batch coding, as well as labeling machines and Shrink-Wrapping Machine.

Utilities Setup: Install necessary utilities such as compressors, electrical installations, air conditioners, and generators to support the operations.

Laboratory Setup: You should set up chemical and microbial testing labs to test the water regularly. These labs will check for things like germs and chemicals to make sure the water is safe for everyone to use.

Make sure your product is really safe and clean by checking it carefully. Set up labs to test chemicals and germs and keep good records for checks by regulators. Getting certified by organizations like the Bureau of Indian Standards (BIS) can make people trust your brand more.

Obtaining Licenses and Permits: It's really important to get all the licenses and permits you need to run your mineral water plant smoothly without any legal issues. This means following all the rules set by your local, state, and national governments.

B.I.S. Compliance: Following B.I.S. standards are a must. Make sure your mineral water plant has the right labs and chemists as required by the rules to keep up with these standards.

Utilize Compliance for Market Leverage: When your mineral water plant meets all the rules, you can use this as a big selling point. It'll attract customers who really care about having safe and high-quality products.

Large capacity Water Filling Machines:

Small capacity Water Filling Machines:

Production Capacity:Choose machinery that will match your current and future production needs of mineral water plant.

Bottle Sizes:Make sure that the machine can handle various sizes of bottles such as 200ml, 250ml, 500ml, 1000ml or 2000ml etc.

Materials Compatibility:You also must see if the machine can handle various materials used for packaging

Cost of Ownership:Also go through the upfront investment, ongoing maintenance, and operational expenses that machinery would require.

Automation Features:Machine that can have automatic features such as automatic rinsing, filling and capping. Also, automatic labeling capabilities of the labeling machine can help you reduce labor costs.

Build Quality:Choose a machine that is made from high-quality materials and for long-term use.

You have to make sure that your mineral water plant has necessary utilities and supporting infrastructure, such as compressors, electrical installations, air conditioning systems, and backup generators. It plays an important role in maintaining optimal operation conditions and minimize downtime.

Preliminary Research: You should first conduct thorough research to understand the specific machinery required for your needs and then create a detailed list of required equipment.

Resource Management: You also have to ensure a reliable water source and appropriate logistics for transportation and distribution.

Initial Investment:You have to first consider the investment required to start a mineral water plant at the initial stage.

Market and Branding: You should select machinery that matches your marketing and branding strategy.

Cost Reduction Strategies: You can consider lower BPM machines or outsource bottle manufacturing to cut down on initial machinery costs.

Traditional Bank Loans: You can consider applying for bank loans since that are a reliable source of capital, but they require a solid credit history and collateral for the same.

Investors: You can also choose to engage with venture capitalists and angel investors who do not only offer funding but also share valuable industry insights. You have to be prepared to possibly share equity and decision-making authorities with them.

Financial Models and Business Plans: You can develop comprehensive financial models and business plans to understand the required investment, expected returns, and growth strategies for your mineral water plant.

Consider Financing Costs:You also need to evaluate factors such as the cost of financing, repayment terms, and collateral requirements when choosing financing options.

Consultation and Networking:You can try to work with financial advisors or accountants and network with industry professionals to improve your financial strategy and funding chances.

Minimize Initial Investment: You must focus on minimizing upfront costs through careful planning, negotiation, and considering various financing options like bank loans, government grants, and private investors.

Build Strong Relationships: You can start by establishing connections with retailers, distributors, and brokers who can manage sales and logistics, ensuring your bottled water from mineral water plant reaches consumers efficiently.

Brand Promotion: You can also promote your brand through online Marketing as well as offline marketing channels.

Strengthen Partnerships: You can collaborate with major retailers, grocery chains, and convenience stores to ensure widespread product availability. Also, consider the potential of e-commerce platforms and online delivery services to meet the growing online consumer demand.

Customer Retention Strategies: You should also consider implementing loyalty programs to maintain strong relationships with your existing customer base. You can try to offer incentives like discounts or rewards for repeat purchases and referrals.

Highlight Distinctive Features: You have to emphasize the unique aspects of your bottled water, it can be purity, health benefits, or environmental sustainability, to differentiate it from mineral water plant competitors.

Tailor Products to Customer Needs: You can first research and understand the specific preferences and needs of potential customers to better tailor your products according to their needs.

Performance Evaluation: You have to regularly assess the effectiveness of your marketing and distribution strategies. Use key performance indicators (KPIs) like revenue, customer satisfaction, and water quality to measure success and make necessary adjustments.

Stay Informed on Market Trends: You have to keep an eye on market trends, competitors' activities, and customer feedback to stay competitive and adapt your strategies accordingly.

In summary of what this article outlines, to start a mineral water plant, you must start from understanding the market and regulatory requirements. You must select the right machinery and financing options to provide the necessary capital for your plant. As we conclude, it’s a must to pay great importance to the strategic planning and implantation in every part of your setting up of a mineral water plant. The tips to securing the finance along with effective marketing and distribution strategies, lay down a path to achieve profitability and sustain growth in a competitive marketplace. For those who want to step into the bottled water industry, the time to act is now.

Remember, success in the Bottled Water Industry depends on your ability to deliver a high-quality product while maintaining a competitive edge. With the right mindset and a solid foundation, your mineral water plant can succeed and stay ahead of the competition.

To start your mineral water plant, contact Aim Technologies to get a free quote today. Our Team of experts are always ready to help you with your queries.

Subscribe To Our Newsletter to get the latest news, updated and amazing offers delivered directly in your inbox.