Borewell to Bottle: How Commercial Mineral Water Plants Purify and Pack Drinking Water

Category : Mineral Water Plant

Posted : May 20, 2025

Clean drinking water is important for maintaining good health. Commercial mineral water plants have a key role in providing purified water from the source to the drinking bottle.

The procedure starts with borewell extraction, where underground water is pumped to the surface and processed to ensure purity and taste using,

- Advanced filtration

- Reverse osmosis

- Mineralization techniques

Once purification is done, the water is hygienically packaged and sealed for distribution to consumers.

This blog explains the detailed steps of how mineral water plants transform raw groundwater into high-quality drinking water.

So now is the time to get started without a delay.

Sourcing the Water: Borewell and Other Sources

The process of water purification starts with selecting a clean and reliable source without compromising on safety. Mineral water plant manufacturers generally pump water from borewells. But, there are many other options available based on local availability and regulations.

Borewell Water Sourcing

Borewell water is extracted from underground sources using deep drilling and pumping systems. It is a popular choice as it provides clean water with natural filtration compared to surface water.

However, borewell water needs purification to remove,

- Extra minerals

- Impurities

- Bacteria

Other Common Water Sources

- Rivers and Lakes are used in areas with plenty of surface water, which needs complete filtration.

- Spring Water is naturally purified through rock layers and offers high mineral content.

- Municipal Water Supply provides processed water but needs additional purification for bottling.

- Rainwater Harvesting is an eco-friendly option, but it also requires complete filtration.

Also read the Growth of the Mineral Water Plant Industry in Africa: Opportunities And Challenges

Importance of Selecting Clean and Sustainable Water Sources

Choosing a pure and reliable water source guarantees,

- Health & Safety: It decreases the risks of impurities and follows regulatory standards.

- Sustainability: It helps to avoid running down the resources and supports environmental protection.

- Consistent Quality: It ensures stable taste, purity, and mineral balance in bottled water.

By choosing the proper water source and advanced purification techniques, the plants provide safe and high-quality drinking water.

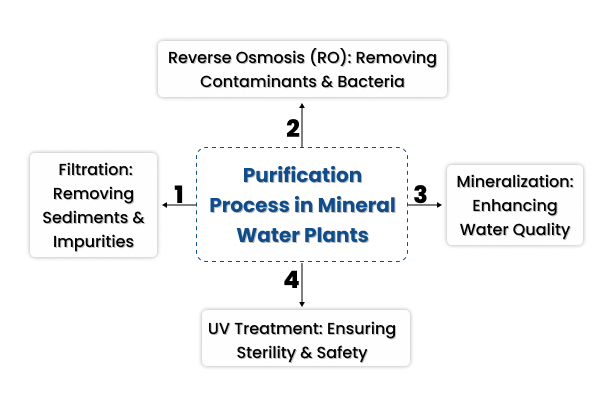

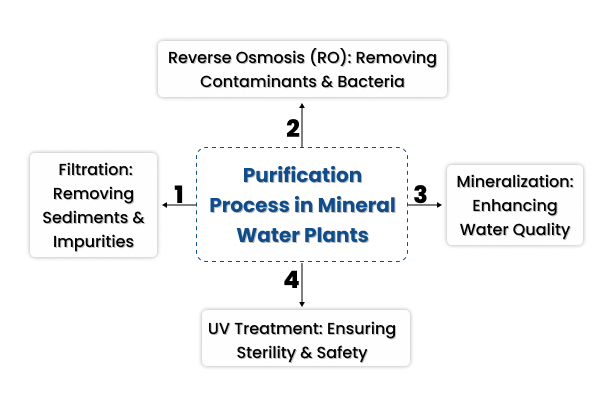

Purification Process in Mineral Water Plants

Commercial mineral water plants use advanced purification methods to deliver safe and high-quality drinking water. Here is a step-by-step breakdown of the water purification process.

1. Filtration: Removing Sediments & Impurities

-

Water passes through different filters to remove

- Dirt

- Sand

- Large particles

-

Activated carbon filtration ensures a better taste by removing

- Chlorine

- Odors

- Organic matter

2. Reverse Osmosis (RO): Removing Contaminants & Bacteria

-

RO layers filter out

- Dissolved salts

- Harmful chemicals

- Microorganisms

- This process delivers ultra-pure water by removing up to 99% of pollutants.

3. Mineralization: Enhancing Water Quality

-

Important minerals are added to provide health benefits like,

- Calcium

- Magnesium

- Potassium

- This step restores the natural balance of the water by improving taste and nutritional value.

4. UV Treatment: Ensuring Sterility & Safety

-

Without changing the water’s structure, ultraviolet light demolishes

- Bacteria

- Viruses

- Harmful pathogens

-

This final step ensures that the mineral water bottle remains

- Safe

- Clean

- Free of impurities

Once water is purified, it is carefully packed into bottles to keep it fresh before reaching consumers.

Read our detailed blog on Packaged Drinking Water Plant: Market Demand and Growth Potential

Bottling and Packaging: From Plant to Shelf

After purification, the final stage is to bottle and pack drinking water to keep it fresh and safe for consumers. This process involves advanced automation and strict quality control measures to maintain hygiene and adeptness.

1. Role of Automated Bottling Plants

Unlike regular packaged drinking water plants, which only purify water, mineral water bottling plants purify water as well as add necessary minerals.

This is performed by following a systematic process as mentioned below.

- Water Sourcing and Purification: The first step is to collect good-quality water from springs, wells, or other reliable sources, then process it to remove impurities and bacteria.

- Addition of Essential Minerals: After the water purification process, mineral water bottling plants add calcium and magnesium to improve the nutritional value.

- Bottling and Quality Assurance: Finally, when the water is purified and minerals are added, the water is bottled with the help of a water filling machine and checked for safety and quality compliance.

2. Quality Control Measures in Mineral Water Bottle Packaging

- Leak and seal checking make sure the caps are properly sealed to avoid water leaks.

- The sterilization process sanitizes bottles before filling to maintain hygiene.

- Material testing makes sure that plastic or glass bottles follow safety standards.

- In batch inspection, random samples are tested to check their purity, taste, and texture.

Automated technology helps mineral water plant manufacturers deliver high-quality mineral water bottles to consumers.

Regulations and Standards for Mineral Water Plants

To ensure the high quality of bottled drinking water, it is necessary to follow government and health regulations. Mineral water plant manufacturers must follow industry standards to maintain hygiene, purity, and consumer safety.

1. Government & Health Regulations for Mineral Water Plants

- The Food Safety & Standards Authority of India (FSSAI) manages the safety and quality of drinking water bottles in India.

- The Bureau of Indian Standards (BIS) introduces guidelines for manufacturing and labeling packaged drinking water.

- World Health Organization (WHO) guidelines set global standards for the quality of drinking water.

- Environmental Regulations manage sustainable water sourcing, handling, and waste removal.

2. Certifications for Safe & Legal Bottled Water Production

- IS 14543 Certification is necessary for packaged drinking water manufacturers in India.

- ISO 9001 & ISO 22000 make sure that quality is managed and food safety standards are followed.

- HACCP (Hazard Analysis and Critical Control Points) detects and controls possible risks in water processing.

- NSF & FDA Approvals are international certifications that verify the product is safe and that quality standards are followed.

3. Best Practices for Compliance & Quality Assurance

- Regular testing is conducted to ensure microbial and chemical analysis to follow safety standards.

- Proper labeling makes sure that the right branding and certification are labeled properly.

- The hygienic bottling process maintains hygiene in the areas where water bottles are filled and packaged.

- Sustainable Practices help follow water protection measures and eco-friendly packaging solutions.

By following strict regulatory standards and getting important certificates, mineral water plants maintain a high quality of drinking water that fulfills consumer expectations.

Market Trends and The Future of Packaged Drinking Water

The packaged drinking water industry keeps growing as demand for safe, convenient hydration increases. Rising concerns about water purity and innovative packaging are shaping the future of the market.

1. Growth of the Mineral Water Plant Industry

- The industry has seen expansion because of urbanization and changing consumer habits.

- Increasing awareness regarding health has increased demand for purified drinking water compared to faucet options.

- Following Government regulations helps to control quality and standards, which improves consumer trust

2. Consumer Preferences & Demand Shifts

- Demand for alkaline and vitamin-enriched water is increasing as health consciousness is in trend.

- Sustainable packaging, including glass bottles and refill stations, appeals to environmentally aware consumers.

- Premium mineral water brands are focusing on purity and natural sourcing.

- E-commerce and direct-to-consumer models transformed the distribution process of mineral water bottling.

With modern technology and changing consumer expectations, the packaged drinking water industry is innovating. Mineral water plants are now offering more sustainable hydration solutions.

Conclusion

Commercial mineral water plants make sure that clean water reaches consumers and helps them maintain good health. From borewell to bottle, each step improves quality and safety, like

- Brewell extraction

- Advanced filtration

- Reverse osmosis

- Mineralization

- Packaging

By following strict regulations and changing consumer needs, the industry keeps growing and is also focusing on eco-friendly solutions. Using advanced technology, Aim Technologies' mineral water plants ensure high quality and hygiene, which fulfill the increasing demand for safe drinking water globally.

FAQs:

Q.1. What is a commercial mineral water plant?

Ans. A commercial mineral water plant is a facility where raw water, usually sourced from borewells or natural sources, is purified and processed to meet drinking water standards before being bottled for sale.

Q.2. Why do commercial mineral water plants prefer borewell water as a source?

Ans. Borewell water is a reliable and consistent source that is easily accessible for many facilities. However, it must be thoroughly treated to meet drinking water standards.

Q.3. What type of bottles are used in commercial mineral water plants?

Ans. Typically, PET bottles are used for commercial bottling due to their durability, transparency, and food-grade quality.

Subscribe To Our Newsletter

Subscribe To Our Newsletter to get the latest news, updated and amazing offers delivered directly in your inbox.