Mineral Water Plant Manufacturer in Gujarat

Category : Mineral Water Plant

Posted : September 19, 2025

Gujarat is still the largest hub for mineral water plant manufacturer providing complete turnkey setups of water bottling plants & packaged drinking water plants. In this guide we review top firms like Aim Technologies, mineral water plant certifications (ISI, BIS, FSSAI), mineral water plant machinery and equipment list and after sales services. With bottled water reaching USD 8.28 billion in 2025 with a 10.51% CAGR, find out how Gujarat can help your business thrive.

Overview: Mineral Water Plant Manufacturer

- Gujarat's Appeal: The state explains its advantages for mineral water plant ventures.

- Key Players: Looking at top mineral water plant manufacturer like Aim Technologies.

- Regulatory Roadmap: Certifications required for mineral water plant (ISI, BIS, FSSAI)

- Tech Choices: For your operation take a close look at automatic vs semi-automatic mineral water plant weighing.

- Gear Guide: The complete mineral water plant machinery and equipment list.

- Sustained Support: Longevity based on After sales service / AMC (Annual Maintenance Contract)

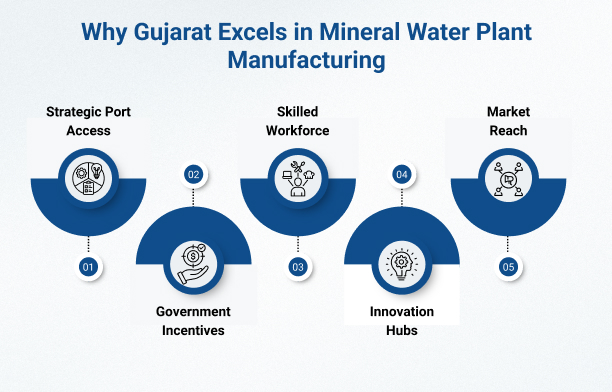

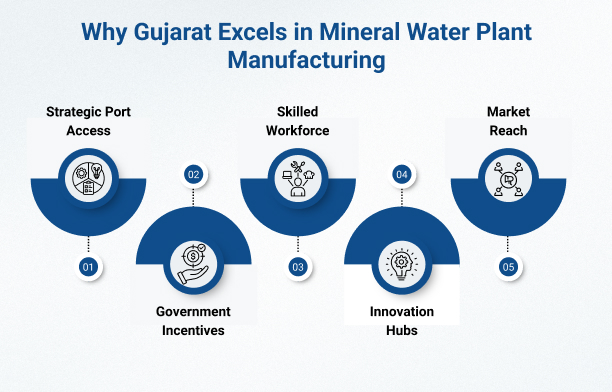

Why Gujarat Excels in Mineral Water Plant Manufacturing

Gujarat accounts for close to 1/4th of India's water treatment equipment output, thanks to clusters in Surat and Ahmedabad that streamline everything from raw sourcing to global shipping. Startups flock here because setups take weeks instead of months and costs are 15-20% below national averages because of local efficiencies.

- Strategic Port Access: Nearness to Mundra and Kandla ports reduces component import time by 40 %, which speeds up the installation of mineral water plant.

- Government Incentives: Gujarat Industrial Policy 2020-25 provides 25% capital subsidies for water bottling plants.

- Skilled Workforce: Over 50,000 technicians ensure smooth operations and quick fixes for complex systems.

- Innovation Hubs: R&D drives 30% increase in output at SEZs in Dahej with water-efficient tech.

- Market Reach: Urban centers like Ahmedabad and Surat fuel local sales, lowering distribution costs for new ventures.

Certifications Required for Mineral Water Plant Compliance

Any mineral water plant must understand the regulatory landscape to avoid penalties and build trust. Obtain ISI, BIS, FSSAI for Mineral water plant required certifications to meet India's tough safety standards of market acceptability. While FSSAI demands hygiene and labelling, BIS/ISI involves testing of water purity-both essential for consumer confidence export eligibility. A reliable mineral water plant manufacturer can guide businesses through these compliance steps as a part of a turnkey setup.

- FSSAI License: Food safety obligatory; Central license cost INR 7,500 for multi-state operations plus hygiene audits.

- BIS/ISI Certification (IS 14543): Mineral content is verified by lab test; Necessary to brand a product as "mineral water"; optional for packaged water since 2024.

- Supporting Documentation: It requires water analysis, plant layouts and GMP certificates; processing takes 45-90 days.

- Local Advantage: Gujarat iNDEX clearance system cuts approval times by 20%, cutting BIS timelines.

- Consequences of Non-Compliance: INR 10 lakh fines or plant shutdowns; annual renewals preclude lapses.

Explore our comprehensive 2025 guide on small scale mineral water plants, covering everything from setup to machinery and cost for a 1000 LPH capacity in India.

Automatic vs Semi-Automatic Mineral Water Plant

The decision between automatic vs semi-automatic mineral water plant setups depends on your production targets, budget, and available workforce. Automated systems are best for large volume packaged drinking water plants and are accurate and fast whereas semi-automatic setups are economical and flexible for smaller operations. A trusted mineral water plant manufacturer like Aim Technologies offer both in Gujarat where scalability is critical so businesses can adapt technology to market demands whether it be urban distributors or rural niches.

- Automatic Systems: Deliver 60-200 BPM robotic rinse-fill-cap cycles with 60% less labor and errors to less than 1%; Suitable for 10,000 + daily bottles.

- Automatic Costs: Range INR 20-45 lakhs with skilled maintenance and higher energy.

- Semi-Automatic Systems: 24-60 BPM, manual tweaking for different bottle sizes (200ml-2L); Ideal for startups or variable runs.

- Semi-Automatic Benefits: It is priced between INR 40-50 lakhs with 20% cheaper spares and lower training requirements.

- Hybrid Options: Start semi-automatic & upgrade modules to meet cost/growth needs of Gujarat's dynamic market.

Mineral Water Plant Machinery / Equipment List

A robust mineral water plant machinery/equipment list is the heart of any good water bottling plant. All components are important - from advanced RO systems to automated packing. Aim Technologies, a leading mineral water plant manufacturer, provides clients with solid, customized mineral water plant setups that include purification, bottling and labeling. This lineup ensures compliance and effectiveness with top-grade bottled water for food, pharmaceutical and other industries.

- Reverse Osmosis (RO) Plant: Filters contaminants via semipermeable membranes. Scales from 1000-20,000 LPH for small to industrial mineral water plants.

- Water Filling Machine: All-automatic, 24-200 BPM; RINSES, fills & caps bottles with little waste. Great for packaged drinking water plants!

- Blow Moulding Machine: Makes PET bottles (12,000 BPH, 200ml-2L); Semi-or full auto for custom shapes & ergonomic designs.

- Labeling Machine: Auto aligns stickers across bottle shapes synchronizing with conveyor speeds to prevent misalignment in high-speed lines.

- Batch Coding Machine: Laser or printer-etches durable expiry dates and lot numbers for regulatory compliance.

- Shrink Wrapping Machine: Heat-shrink film secures packs (5-18 packs); Beverages, cosmetics & pharma available in semi/full auto.

- BIS Consultancy & Lab Equipment: Provides testing kits for TDS & microbial checks in accordance with ISI quality control.

See why the right mineral water plant manufacturer is essential for success in the fast-growing global bottled water sector.

Prioritizing After Sales Service and AMC for Operational Reliability

Post-setup comes the real marathon and that's when after sales service and Annual Maintenance Contract (AMC) becomes your safety net. Packages from mineral water plant manufacturer include quarterly tune-ups and emergency callouts to keep 80% of breakdowns away that could leave lines idle for days.

Aim Technologies develops tailored AMCs from RO membranes to nozzle filling, operator training & 24/7 hotlines with 95% uptime. In Gujarat's humid climate, proactive checks avoid scale buildup in pipes. Beyond fixed upgrades like IoT sensors for remote monitoring are also offered by manufacturers. Choosing a local provider like Aim means response times under 2 hours.

Summing Up Gujarat’s Mineral Water Plant Manufacturer Expertise

These insights help entrepreneurs to enter into the bottled water market which is going to worth

USD 13.65 billion in 2030. Partnering with a reliable turnkey mineral water plant manufacturer enables businesses to turn water into wealth precisely and economically. At Aim Technologies we make your vision a reality with a fully operational water bottling plant personalised to your requirements. Get in touch with us today for a customised consultation & to know more about the cost of setting up a mineral water plant.

FAQs:

Q. What are the different capacities of mineral water plants (LPH or BPM)?

A. Mineral water plants come in 1000–10,000+ LPH options and bottling machines from 40–120+ BPM, depending on production needs.

Q. How to choose a good mineral water plant manufacturer?

A. Check for industry experience, certifications (ISI, FSSAI, BIS), machine quality, after-sales service, and client reviews before finalizing a manufacturer.

Q. What are common mistakes to avoid when buying a mineral water plant?

A. Avoid ignoring certifications, buying low-quality machinery, neglecting scalability, overlooking maintenance, or misjudging market demand.

Subscribe To Our Newsletter

Subscribe To Our Newsletter to get the latest news, updated and amazing offers delivered directly in your inbox.