Shrink wrapping involves using heat shrinkable plastic film to closely and securely package products. A shrink wrap film is a plastic polymer film that shrinks tightly when heat is applied. As a leading shrink wrapping machine manufacturers, we understand how industrial packaging requires precision, products like bottles, boxes, trays are grouped together and then wrapped with film. The wrapped bundle is heated inside a tunnel or a chamber to cause the shrink film to contract tightly around the contents, thus forming a sealed package. The package is firm enough to protect its contents from dust, moisture, or any damage while in storage or during transportation. Shrink wrapping finds applications in food, beverage, pharmaceutical, cosmetic, and many other industries as it provides a clear, tamper-evident package that enhances product presentation.

As per shrink wrapping machine manufacturers, the process of shrink wrapping at large is made of three steps:

For small volumes, these steps can be done manually. The shrink wrapping machines seal and shrink the film at high speed and with better consistency.

Shrink wrapping yields plenty of benefits for manufacturers and packers. Some of the primary benefits are:

In combination, these benefits may make shrink wrapping largely more cost-effective and protective than most other packaging means (boxes, stretch wrap, etc.).

Ask these 10 key questions before choosing your shrink wrapping machine manufacturer - know more to make the right decision.

Shrink wrapping machine manufacturers provided various configurations to fit production needs. Usual categories are semi-automatic or fully automatic machines, with form-factors of L-bar sealers, and linear in-line systems. In general:

Semi-automatic wrappers require a human operator load product, but the films sealing and shrinking is offered autonomously. Great for small-to-medium size production runs.

Fully automatic wrappers package continuously at very high volume with practically no human intervention. Products may be fed by means of conveyors, sealed in film, and introduced into a tunnel.

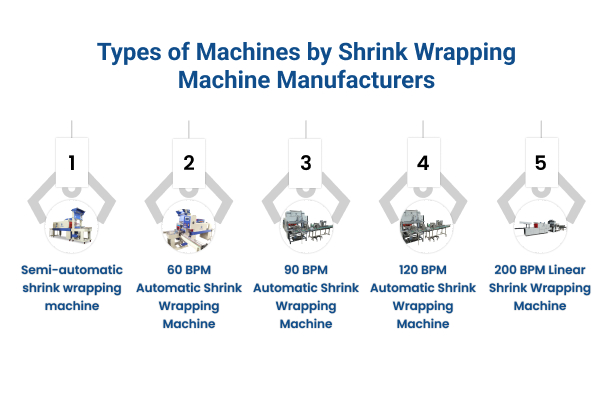

The main types sold by shrink wrapping machine manufacturers are as follows:

The semi-automatic shrink wrapping machine works by manual loading but sealing and shrinking are done automatically. The operator placed bundled items (several bottles or boxes) inside the seal bag area of the machine. The machine wraps the group in shrink film, by automatic means, seals the edges of the shrink film and then runs the pack through a heated chamber or tunnel to shrink.

It increases the throughput as compared to hand-wrapping while maintaining costs at a low level. Aim Technologies point out that their semi-automatic wrappers "are most suitable for small and medium industries" and "deliver consistent high-quality shrink-wrapped products". For example, in a typical chamber sealer operation, the operator puts the product in a film sleeve, and the machine simultaneously seals and shrinks the film around the product. The end result is a tight pack able to be handled or sold.

A 60 BPM automatic shrink wrapping machine is an all-automatic machine designed to accommodate continuous production of a moderate speed. At the speed of 60 BPM, the machine wraps 0-5 packs per minute. In other words, the products are automatically bundled (for example on a conveyor), sealed in film, and then are conveyed through a hot-air tunnel, all without stopping the production line. It is emphasized that the 60 BPM model by Aim Technologies largely "reduces labour costs and increases overall efficiency." It is, in fact, fully automatic and wraps the products in a most professional manner, and thus, each of its packages is consistent.

Such machines are best applied to medium-sized beverage, cosmetic, or food lines. In the sense of higher speeding than semi-automatic machines, these reject extremely high throughput levels.

The 90 BPM automatic shrink wrapping machine has higher packaging capacity for larger facilities. It can shrink-wrap 0-8 packs per minute. Usually, the grouped products are fed in a continuous flow to the sealing and heating sections. According to Aim Technologies, the 90 BPM machine would "wrap your bottles in a group" and is designed to "handle different size" containers while keeping a secure seal. In practice, this system groups items of various sizes and wraps them into bundles automatically. The high speed, combined with flexible size options, makes this 90 BPM shrink wrapper ideal for large beverage or chemical manufacturers that need to shrink-wrap medium batches efficiently. Each wrapped bundle is securely sealed protecting the products during shipment.

In essence, the 120 BPM shrink wrapping machines are built for high-speed, heavy-duty production lines. Because these packs work at 0-10 packs per minute, they can run almost perpetually with a scant possibility of downtime. Aim Technologies categorizes their 120 BPM wrapper as "ideal for high-volume production lines" and further notes that it works continuously with very little maintenance. While the sealing and shrinking steps are fully automated with a 120 BPM system, this provides a dramatic increase in output and consistency while simultaneously decreasing manual labor.

A shrink wrapping machine manufacturers describe the 120 BPM wrappers as a "high-performance solution for efficient and precise bottle packaging that limits manual interventions and maximizes productivity." To put it simply, this means that the great factories use 120 BPM machines to package thousands of bottles per hour without compromising quality.

Linear shrink wrapping machines with 200 BPM rate were at the top. These in-line machines operate up to 0-18 packs per minute, suitable for the fastest production environments. Aim Technologies mentions that their 200 BPM linear wrapper is "designed for high-speed, efficient packaging" and can wrap up to 200 bottles per minute. It is fully automatic with a straight conveyor path: product comes in, film wrapping and sealing, shrink tunnel passing, all done continuously.

The 200 BPM model is mostly used in large beverage, food, or pharmaceutical plants. Aim mentions that it packages bottles, cans and containers of the beverage, food, pharmaceutical and personal care sectors. This class of machines increases throughput greatly and tightly seals each bundle.

Discover the top benefits of shrink wrapping machines for packaging - know more here.

Depending largely on your production volume, product type, and price, the selection of the appropriate shrink wrapping machine varies. High production speeds obviously mean high packing speeds and vice versa. Machines are generally specified by their capacity in packs-per-minute. For example, a 60-BPM machine functions at 300 units per hour, whereas one rated at 200 BPM could process as many as 1,080 units per hour.

Semi-autos or fully autos with smaller BPMs may fill the bill for small operations, whereas extremely large volume lines of about 120-200 BPM capacity are the place to operate. A reliable shrink wrapping machine manufacturers recommend that machine speed must be aligned with line shrink-wrappers of 120 BPM for lines relatively producing 120 bottles per minute. The number of items going in one bundle (pack configuration) and the dimensions of the products should also be considered, along with how this shrink wrapping machine will combine with upstream conveyors/collation systems.

Aim asserted that semi-automatic machines are "most suitable for small and medium industries" because of their easy operation, while fully automatic models pay off when handling continuous large batches. By assessing all of these factors, you are ensured a shrink wrapper that improves efficiency and yet is not paid out for useless capacity.

Shrink wrapping machines should improve the packaging speed, protect the product and present it well. They range from semi-automatic types meant for small plants to high-speed automatic systems used by big factories. Shrink wrapping machine manufacturers like Aim Technologies offer a full series of shrink wrapping machines to satisfy these needs.

When buying from Shrink Wrapping Machine Manufacturers such as Aim Technologies, you are assured of fast and dependable packaging with the added benefit of product protection and presentation. Their machines are designed to accept products of various dimensions and processes. Hence, you will get one right for your line of production.

A. Decide based on volume and labor. Manual L-bar sealers are low-cost but slow, ideal for small businesses. For hundreds of units per hour, a fully automatic shrink wrap machine is more efficient.

A. Experienced manufacturers ensure better design (e.g. even heat distribution, safety features) and ongoing support. They also understand region-specific requirements (like voltage differences in India or South Africa) and can provide local technical assistance or training.

A. High speed (capacity), hygiene (stainless parts), size flexibility (adjustable guides), and reliable sealing. Machines should ensure leak-proof, tamper-resistant bundles. Look for easy film loading and quick changeover if running different bottle sizes.

Subscribe To Our Newsletter to get the latest news, updated and amazing offers delivered directly in your inbox.