Are you struggling to find the right water bottle filling machine for your business? With so many options available, it can be overwhelming to choose the one that best meets your needs.

Whether you're looking to scale up your production or improve efficiency, having the right features for your water bottle filling machine decides how well it will perform.

But how do you know which features to look for? Worry not! We’ve got you covered!

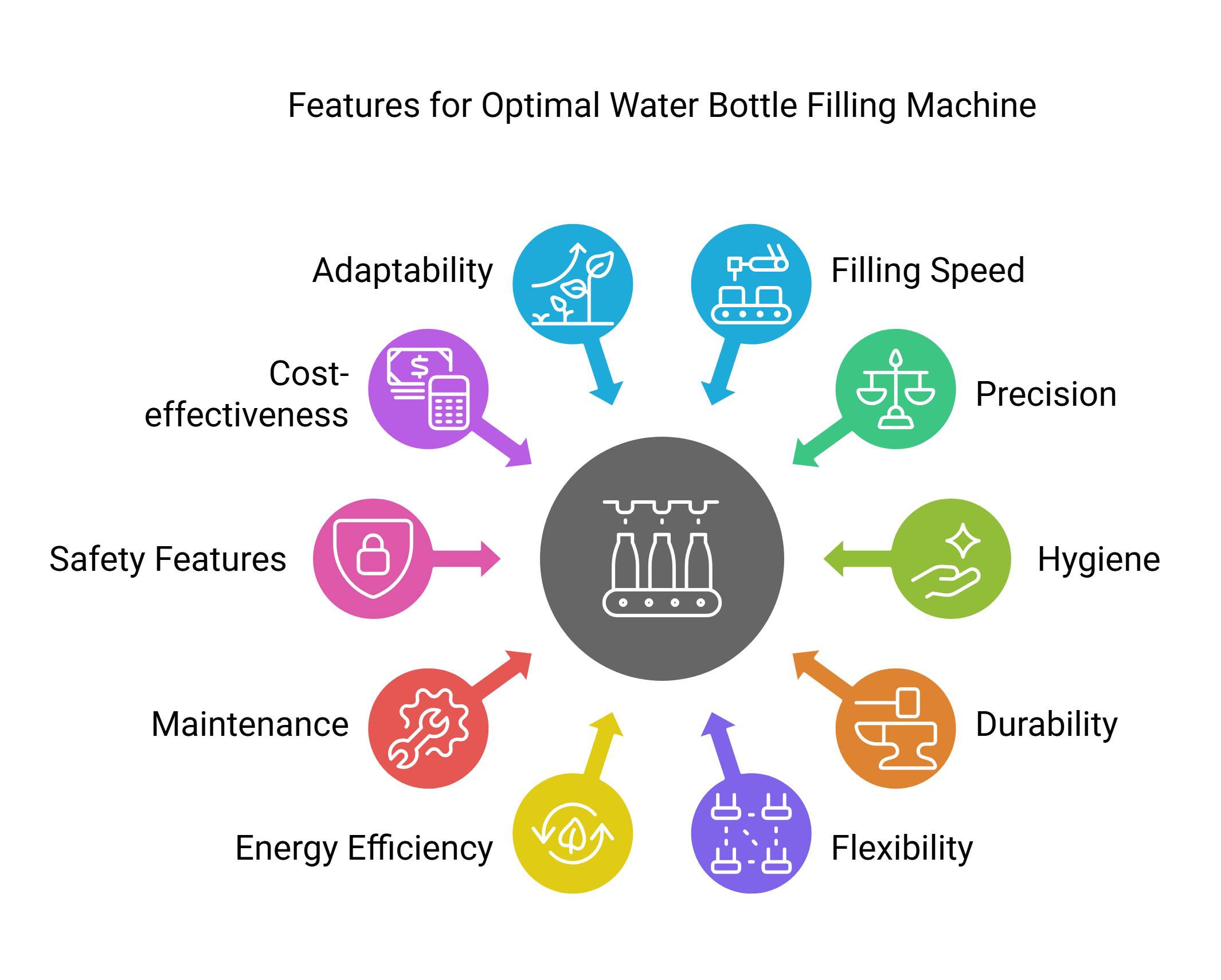

n this blog, we’ll walk you through the top 10 features to look for when selecting a water bottle filling machine that will help streamline your operations and boost your business growth.

So, let’s get started without any further delays!

Regardless of the type of water bottle filling machine you want to buy, considering the below-mentioned factors will help you make an informed decision.

When it comes to water bottle filling machines, speed is often a top priority.

A high-speed machine makes sure that your production line keeps moving at full speed, minimizing downtime and maximizing productivity.

Additionally, when you choose an automatic water filling machine, it will typically offer you faster filling speeds than manual options. This further helps you keep up with high demands while improving overall efficiency.

Depending on your business's needs, you can choose a machine that has both speed and precision. If the machine is filling too slowly, you risk falling behind and if it fills too fast, you may face issues with over production.

The best option is to look for a machine that allows you to do customization of speed so that you can adjust it to your production requirements.

Once you are sure about the filling speed and efficiency, you need to check the accuracy of water bottle filling machines.

Overfilled or underfilled bottles not only waste products but can also lead to customer complaints or regulatory fines.

People today are more concerned about their health and want to access safe and hygienic water

When you choose the best water bottle filling machines, you can have technologies like flow meters and level sensors to make sure that the right amount of water is dispensed into each bottle.

For mineral water filling machines, precision becomes even more important as the water's consistency is a selling point. These machines ensure that each bottle in your manufacturing unit is filled consistently, providing both your customers and your business with high-quality products.

In the bottled water industry, cleanliness is non-negotiable. A machine that is not easy to clean can lead to contamination which compromises the quality of your water.

If you look around in the market, you will see that the best water bottle filling machines come with hygienic designs and easy-to-clean components.

It is recommended that you choose a machine that has stainless steel construction, self-cleaning systems, and anti-bacterial coatings. All of these in a water bottle filling machine make sure that the machine remains clean and healthy even during long production runs.

The hygiene and cleanliness aspects are even more important for mineral water filling machines, as they deal with water that must remain free from contaminants.

Before you buy any water bottle filling machine, make sure that the machine you choose is in compliance with industry hygiene standards to avoid legal issues in the future.

Other than the features discussed above, machine durability and quality also matter to a great extent because a water bottle filling machine is an investment in your business, and you need to make sure it's a robust one.

Machines that are made from high-quality materials such as stainless steel tend to last longer and perform better in high-demand environments. It will also be able to endure high usage and have a low risk of breakdowns, making your production cost-effective.

So, whether you decide to buy an automatic water filling machine or a mineral water filling machine, ensure that the build quality of the machine is robust and capable of withstanding the rigors of daily operations.

When choosing a water bottle filling machine, you need to keep in mind that not all businesses produce the same types of bottles, so the machine you choose should be flexible enough to accommodate different sizes and shapes.

Whether you're filling small bottles for on-the-go hydration or larger containers for bulk sales, your machine should adapt accordingly.

There are also some automatic water filling machines that offer adjustable settings for different bottle sizes, making them a preferred choice for businesses that handle a wide range of product types or plan to diversify their offerings over time.

Moving next, another important feature that you should look at in a water bottle filling machine is energy efficiency.

Today when people are becoming more environmentally conscious, having energy-efficient machines is not just about cost-saving but also a responsibility. So, when you choose a machine that is designed with energy efficiency in mind – you not only save on utility bills but also contribute to achieving bigger sustainability goals.

Plus, you can highlight a smaller carbon footprint as an added advantage which can be a great selling point for eco-conscious consumers.

There is no doubt that no matter which machine you buy, you will need to put some effort into its maintenance. In such cases, it’s better to look for options where you don’t need to put extra effort into maintenance.

Look for machines that have user-friendly interfaces, self-diagnosing systems, and easy access to parts that may need replacement. Moreover, regular maintenance checks should be simple and quick to complete so that you can minimize any downtime.

Also, ensure that your supplier has reliable customer support in case you face any issues with the machine in the future.

Having a mineral water filling machine with excellent customer support and minimal maintenance can be a great asset to your business.

Going further, safety is quite critical in any production environment, especially when you're dealing with machinery that operates at high speeds.

Look for water bottle filling machines that have built-in safety features like emergency stops, overload protection, and safety guards. These features will protect your operators and keep the work environment safe.

Let’s be honest here: whenever a business invests in an asset, it needs to consider its returns on that investment.

When selecting a machine, it’s important that you consider the total upfront cost of the machine along with other costs like maintenance and operational costs.

Consider your short-term and long-term goals and see what output you can expect with this investment and make a decision accordingly.

Lastly, consider the future of your business. The ideal water bottle filling machine should not only meet your current production needs but also be adaptable as your business grows.

Look for machines that can be upgraded or modified to accommodate new bottle designs, different types of water products, or higher production volumes

Choosing a machine that can be a great fit for your business’s future too is a good choice and makes sure you are getting good returns on your investments.

We hope with all the information provided above in the blog; you now know about all the features to look for while considering a water bottle filling machine.

Whether you're looking for an automatic water filling machine or a mineral water filling machine, these features remain almost the same.

If you are planning to set up a water bottle filling machine for your business, feel free to get in touch with our team at Aim Technologies to set up the right water bottle filling machine for your business.

A. A fully automated water bottle filling machine reduces manual labor, improves filling accuracy, and increases production speed. Automation also provides better control over the filling process, leading to higher quality products.

A. Maintenance tasks for the water bottle filling machine include cleaning, sanitizing, checking for wear and tear, inspecting the filling nozzles for blockages, and ensuring that the sensors and pumps are functioning properly.

A. To choose the right filling speed, you need to look at your business's production capacity and the demand for your products. If you have a high-volume operation or experience seasonal spikes in demand, you should go with a high-filling speed machine. However, if you have a smaller business with steady demand, you can go with a slower but more precise machine filling speed.

Subscribe To Our Newsletter to get the latest news, updated and amazing offers delivered directly in your inbox.