Have you ever felt like your production line could do more, but your equipment is holding you back?

Well, you’re not alone.

Many businesses struggle to keep up with growing demand, rising labor costs, or strict hygiene standards, all because their filling systems aren’t keeping pace.

Whether you're scaling a small operation or managing a full-blown manufacturing unit, the right bottle filling machine is one of the most critical investments you'll make.

In this guide, we’ll cut through the noise and help you choose a machine that actually fits your production needs, not just today, but it will help you make informed decisions even when your business grows!

Let’s begin by getting a quick understanding of what a bottle filling machine is.

A bottle filling machine is designed to fill containers with liquid products, such as water, juices, oils, chemicals, or cleaning fluids.

Depending on the product and the production requirements, these machines vary in design, automation level, speed, and accuracy.

When you select a well-matched bottle filling machine that fits your business requirements, it makes sure that you get precision, hygiene, and speed with minimal waste.

Explore the top 10 features to look for in a water bottle filling machine for efficient and consistent operation.

Every production line has its own rhythm, and the machine you choose needs to complement that rhythm.

A mismatch in machine selection may lead to inefficiencies, worker fatigue, and missed targets.

On the other hand, choosing the right machine results in -

In short: the right bottle filling machine doesn’t just fill bottles; it fuels your business growth too.

But how do you know which type of water bottle filling machine is the right fit for you? Let’s find that out in the following sections by exploring the types of bottle filling machine.

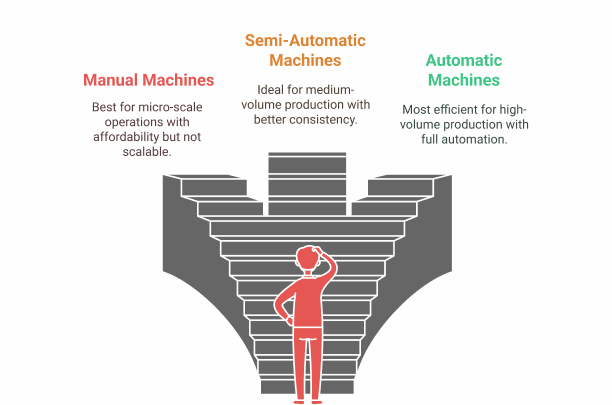

Best suited for micro-scale operations, these machines rely entirely on human effort. Operators must manually load the bottle, control the fill, and remove the finished product. They're affordable but not sustainable for businesses expecting to scale.

These are hybrid systems. An operator may place the bottle, but the machine handles the filling. Great for medium-volume production as they provide better consistency and are easier to maintain than fully manual setups.

Automatic machines are the gold standard for efficiency. An automatic bottle filling machine handles everything starting from feeding and aligning bottles to filling, capping, and sometimes rinsing the bottle.

They can run continuously with minimal supervision, making them ideal for businesses focused on volume, hygiene, and cost control.

So which one is the right choice for you?

Well, if you are on a smaller scale and have limited capacity and investment budget, you can go with a manual machine.

However, if you have more volume to cater for and want to automate the process to some level, semi-automatic machines are the best choice for you.

And finally, when you are planning to go on a huge scale with minimal human innervation, investing in fully automatic machines would be a wise choice.

No matter which water bottle filling machine you choose, here’s what a good bottle filling machine should include -

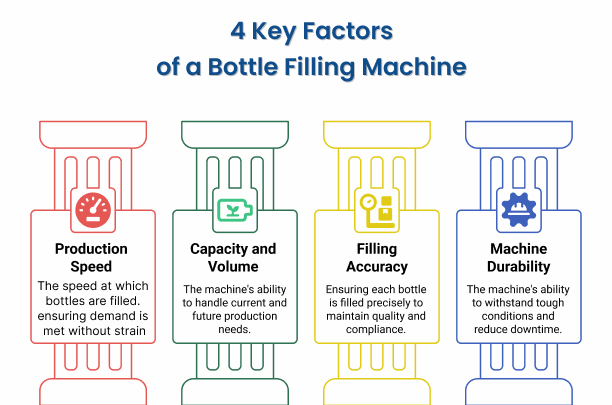

Before you make an investment in a mineral water filling machine, there are some factors that you need to consider ensuring you are making a wise decision.

The first and foremost thing you need to consider is - how fast do you need to go? Production speed is more than just BPM (bottles per minute); it’s also about matching demand without overloading your team or infrastructure.

An automatic bottle filling machine can fill up to 200 bottles per minute or more, but make sure your downstream operations (like labeling) can keep up with that.

Choose a machine that suits your current capacity but also leaves room to grow. You need to make sure you are not overspending on buying more capacity and not limiting your future growth by spending too little on the capacity.

To avoid this situation, ask yourself -

When you have clear answers to these questions, you can make better decisions that align with your business goals.

The cost of inaccuracy can add up very fast, especially in high-volume production.

But a good automatic bottle filling machine ensures each bottle is filled to the exact level with minimal variation.

This not only keeps customers happy but ensures regulatory compliance and reduces overfill loss.

Moving next, for anything involving consumables or chemicals, durability isn’t optional, and thus it is important to prioritize machines built with -

There’s no doubt that durable machines reduce maintenance downtime and last longer under tough factory conditions.

After learning quite a few things about water bottle filling machines, let’s talk about how you can evaluate the cost of these machines.

The cost or investment needed for a water bottle filling machine may vary based on the model you choose but to evaluate the real value of your investment, you need to look beyond the purchase cost.

Remember, a cheap machine with high maintenance needs will cost more in the long run.

Water bottle filling machines are energy-efficient motors or smart automation panels reduce power bills and also reduce human errors too.

So, a high-quality mineral water filling machine might have a higher upfront cost, but when your product’s reputation relies on purity and precision, you can’t afford failures.

Finally, when you choose the right kind of right bottle filing machine, there are many benefits you get along with it as mentioned below -

The right automatic bottle filling machine can double your output with the same workforce. Integrated systems cut down manual handling and streamline production.

Labor, energy, cleaning, product loss, all these costs go down when your machine is built to fit your needs. A reliable automatic water filling machine pays for itself within months by reducing overheads.

Finally, precision fills = happy customers. A good machine also reduces contamination risks, especially in sensitive products like mineral water.

Whether you're filling 500ml bottles or 2000ml cans, the right mineral water filling machine helps you meet regulatory standards while delivering consistent, clean, and safe products.

A bottle filling machine isn’t just a purchase, it’s a partnership. The right one will grow with your business, improve your product quality, and optimize your entire line.

When evaluating options, always consider:

At Aim Technologies, we don’t just sell machines, we help businesses build production systems that last.

Whether you need a high-speed automatic water filling machine or a specialized mineral water filling machine, get in touch with our team to discuss more about your requirements.

Ans. If you're consistently producing more than 3,000–5,000 bottles per day, and labor is becoming an issue, it’s time to automate. Also, consider your growth projections and peak demand seasons as well to decide when you should buy an automatic bottle filling machine.

Ans. To maintain mineral water filling machine in its best condition, it’s recommended -

Routine maintenance ensures longevity and avoids downtime during peak seasons.

Ans. While automatic machines are designed for ease of use, basic operator training is essential. This typically includes learning how to set up batches, monitor fill levels, handle errors, and conduct routine maintenance. We, at Aim Technologies, offer onboard training as part of our post-sales services.

Subscribe To Our Newsletter to get the latest news, updated and amazing offers delivered directly in your inbox.