From 20 to 200 BPM: Which Sticker Labeling Machines Suits Your Industry?

Category : Sticker Labeling Machine

Posted : August 25, 2025

If you're in packaging and need to label products efficiently, selecting the right sticker labeling machine can transform your operations. This article describes how sticker labeling machines fit different production speeds from 20 to 200 bottles per minute (BPM). Types like automatic sticker labeling machines and bottle labeling machines are described and matched with sectors like food, pharmaceuticals and cosmetics. Practical advice on features, market trends and selection. See why automatic labeling machine manufacturers and sticker labelling machine suppliers in India choose Aim Technologies.

Blog Overview

- Understanding BPM in Labeling: Learn what bottles per minute is and why it matters for your production line in Labeling.

- Types of Sticker Labeling Machines: Explore manual, semi-automatic, and fully automatic sticker labeling machines, including wrap around labeling machines and front and back labeler machines in India.

- How Does a Sticker Labeling Machine Work?: A step by step breakdown of A Sticker Labeling Machine process from conveyor feeding to label application.

- Matching Machines to Industries: See which speeds and types suit food, beverages, pharmaceuticals, cosmetics, and more.

- Key Features to Consider: Focus on speed, accuracy, customization and maintenance are important for long term success.

- Market Trends and Growth: Insights into the expanding sticker labeling machine market and what drives it.

- Tips for Choosing a Supplier: Guidance on selecting sticker labelling machine suppliers like Aim Technologies.

What is BPM in Labeling

BPM stands for Bottles Per Minute and is the beating heart of any labeling operation. This directly affects your daily output and affects your whole packaging chain from filling to capping.

- Matching Line Speed: A high-speed bottling Line requires a complementary labeling pace. Bottlenecks in production occur when your filling machine runs at 100 BPM but the labeling unit runs at 60 BPM.

- Versatility in Scale: Whether you run a startup operation or a large scale manufacturing, BPM helps you make the right decision. Manual systems under 20 BPM serve for small batch operations; semi-automatic setups (50-100 BPM) serve for midsize needs; fully automatic setups (150-200 +) serve for heavy industrial runs.

- Future-Proof Planning: Investing in modular or scalable machines future-proofs your line. Once you start with the right Sticker Labeling Machines, growth in demand will not require full replacement but just an upgrade in throughput.

In combination, these benefits may make shrink wrapping largely more cost-effective and protective than most other packaging means (boxes, stretch wrap, etc.).

For a complete overview of their types, unique features, and wide range of uses, check out our blog on Sticker Labeling Machines: Types, Features and Applications.

Types of Sticker Labeling Machines

Sticker labeling machines are available in various configurations to suit different production requirements from small production runs to large scale industrial lines. Understanding available types helps you choose the right machine for your products/throughput goals. At Aim Technologies, a leading automatic labeling machine manufacturer, we have machines for food, beverages, pharmaceuticals and cosmetics industries.

- Single-Side Sticker Labeling Machines: These Single-Side Sticker Labeling machines apply labels on one side to flat bottles or containers. Ideal for beverage industry. They support taller and longer labels up to 200 BPM with advanced dispensing systems.

- Front and Back Labeling Machines: Such flexible front & back labeler machines apply labels on both sides of flat, oval, square or round containers simultaneously. Their outputs are up to 200 BPM and are ideal for jars with nutritional and branding labels for food and pharma products.

- Round Labeling Machines: Specially designed for cylindrical containers, round bottle labeling machines like these wrap labels around bottles of drinks or pesticides. They feature microprocessor-controlled dispensing for precision and can process larger label sizes at competitive speeds of 150 BPM.

- Customized Labeling Machines: Customized Labeling Machines are designed for special bottle shapes or sizes. So a cosmetics brand with irregular shaped containers can use sticker labelling machine suppliers like Aim Technologies for bespoke solutions to ensure label placement.

- BOPP Labeling Machines: They apply hot-melt BOPP labels often found on beverage packaging. They work well in high-speed lines and with other bottle sticker labeling machines for consistent branding.

- Shrink Sleeve Applicators: They apply shrinkable sleeve labels to bottles of all shapes and sizes. They increase production rates by automating sleeve cutting and positioning for industries requiring tamper-evident packaging.

All types are flexible to meet business needs from low-cost manual options to high-speed automatic sticker labeling machines.

How Does a Sticker Labeling Machine Work?

A sticker labeling machine moves through coordinated steps. Products move on a conveyor belt slowly. All items are detected by sensors as they approach the labeling head. It then peels a label from a roll if adhesive is needed and presses it onto the container.

For an automatic sticker labeling machine precision is provided by rollers and guides which align labels. Rotating mechanisms in bottle sticker labeling machines assure even application around curves! The process ends with a smoothing brush or roller to secure the label without bubbles or wrinkles. This automation eliminates errors and provides speed so it is useful on busy lines.

Take a beverage factory: Bottles come off a conveyor, are labeled front & back, and are out for packing in seconds.

Which Sticker Labeling Machine Suits Your Industry?

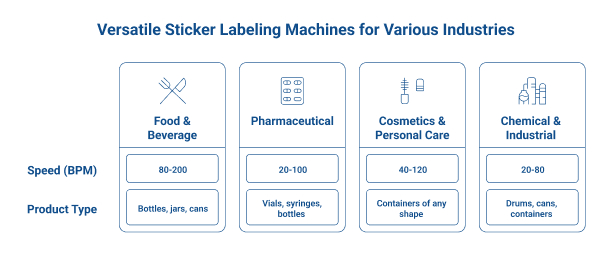

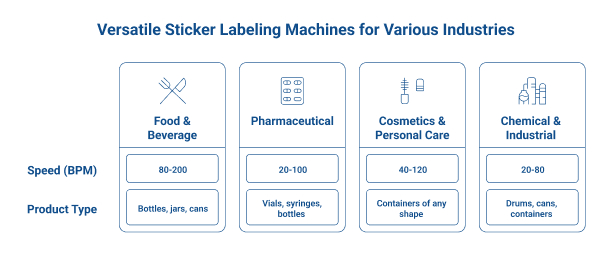

Different industries need specific sticker labeling machines according to speed and product type.

- Food & Beverage (80-200 BPM): Great for fast application of product labels, nutrition facts, branding on bottles, jars and cans without losing accuracy.

- Pharmaceutical (20-100 BPM): Accurate placement of label on vials, syringes and medicine bottles at controlled speed in compliance with regulations and traceability.

- Cosmetics & Personal Care (40-120 BPM): High quality, wrinkle free labels for containers of any shape.

- Chemical & Industrial (20-80 BPM): For labeling of drums, cans and containers at moderate speeds; durable in harsh conditions.

Key Features to Consider

The choice of a labeling machine goes beyond counting bottles per minute. The following are the core qualities to consider:

- Speed & Accuracy: Velocity and precision are needed for Labeling equipment. High end automatic units achieve millimeter consistency at high throughput, reducing mislabeling and maintaining brand integrity.

- Adaptability Across Formats: Leading automatic sticker labeling machines can handle wrap-around, front-and-back or full body sleeves labels. Such flexibility reduces changeover time and meets different product packaging requirements.

- Ease of Maintenance: Seek out quick-access components, tool-free adjustments and smart diagnostics. This reduces downtime and allows faster changeovers during production shifts. Transitions from semi-automatic to fully automated transitions should be as smooth as possible.

- Integration Readiness: The true power of Sticker Labelling Machines is their integration with upstream/downstream systems like fillers, caps and conveyors. Line efficiency and misalignment problems are avoided through smooth synchronization.

- Compliance & Durability: For food, pharma or cosmetic sectors, compliance matters. Stainless steel, washdown enclosures and food-safe contacts improve hygiene and regulatory alignment.

- Operator Interface & Automation: Modern machines have touchscreen HMIs, recipe changeovers, and remote diagnostics. Some labeling lines cut labor costs by 25-40% and error rates by 80%.

To understand how these machines streamline operations, read our detailed blog on How Sticker Labeling Machines Improve Efficiency in Packaging.

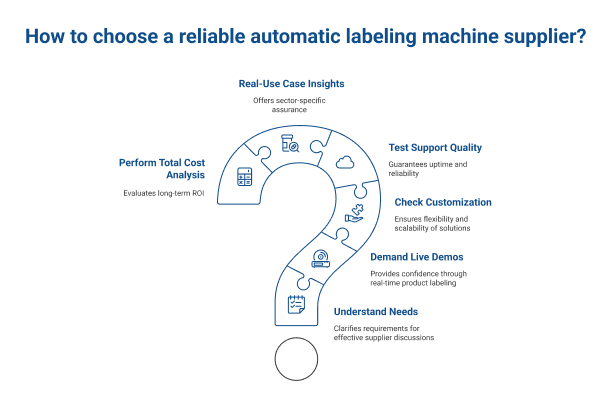

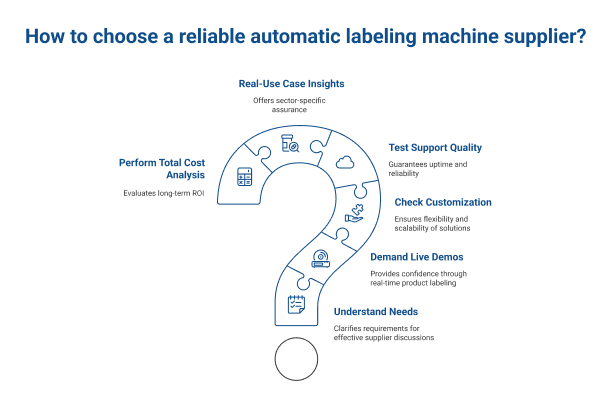

Tips for Choosing a Supplier

To select reliable automatic labeling machine manufacturers, look for certifications like ISO. See machines in action at facilities or request demos.

- Understand Your Needs: Consider upfront cost, production goals, pain points & regulatory requirements. This clarity simplifies supplier discussions - as in food production where sanitation and precision are non negotiable.

- Demand Live Demos: Request on-site or video demonstrations with your actual containers & labels. Watching your product being labeled in action gives you unmatched confidence.

- Check for Customisation: Your supplier should offer modular scalable solutions, add heads, speeds or label formats without replacing the whole system.

- Test Support Quality: Fast spare parts delivery, remote troubleshooting and training. These can make or break machine uptime. It helps having local service coverage.

- Look for Real-Use case Insights: Ask for Case studies within your sector. If they can sell you a bottle labeling machine for foods or pharmaceuticals, that matters more than generic specs.

- Perform Total Cost Analysis: Conduct Total Cost Analysis and Compare caps to ROI on energy use, labor reduction, waste savings & maintenance uptime - not just the purchase price.

See reviews & case studies from related industries. Reliable sticker labelling machine suppliers provide after-sales service including training and spare parts. The local suppliers cut shipping times and customize solutions for India.

Why Aim Technologies Excels in Sticker Labeling Machines

From small-scale setups to high-speed production lines, we understand what you face in labeling. From 20 to 200 BPM speeds, types such as automatic sticker labeling machines or bottle labeling machines and their applications to food and pharmaceutical industries are described in this article. We explained operations, features and trends so you can choose wisely. Looking for the right sticker labeling machine? Reach out to Aim Technologies for advice & custom solutions. Get a quote from our experts today.

FAQs:

Q. What does BPM mean, and how is it different from line speed?

A. BPM (bottles per minute) is the labeler’s nominal application rate. Line speed is the end-to-end throughput of your entire packaging line. Your true output is limited by the slowest station (e.g., filler/capper/conveyors), so a 200-BPM labeler may still run slower if upstream/downstream steps bottleneck. Size to your line speed, not only machine BPM.

Q. Which BPM range suits my operation?

A. 20–40 BPM: pilots, startups, short runs, manual/semi-auto. 50–120 BPM: SMEs on automatic linear systems. 150–200 BPM: high-volume beverage/pharma/cosmetics on high-speed systems (often rotary). The right choice depends on container geometry and label length.

Q. Rotary vs. linear labelers: which should I choose for 150–200 BPM?

A. Rotary platforms are typically preferred at sustained ≥150 BPM because they stabilize and orient containers more precisely at speed. Linear autos are excellent for 50–120 BPM and mixed formats. Consider format changeover needs and footprint, too.

Subscribe To Our Newsletter

Subscribe To Our Newsletter to get the latest news, updated and amazing offers delivered directly in your inbox.